Dish Wash Bar Making Machines

We are Manufacturers and Exporters of dish wash bar making machine. We have extensive collection of great quality dish wash bar making machines which are custom-made as per client requirement. We are leading manufacturer of dish wash bar making machine.

MATCON manufacturers the equipments for dish wash bar manufacturing as below.

- Automatic round bar cutting machine

- Automatic slicing machine ( no of cake may be 6-10 nos/stroke )

- Automatic dish wash container dispensing machine

- Automatic rotary stamping machine

- Automatic scrubber feeding machine

- Automatic dish wash container cap feeding and closing machine

- Automatic top label applicator

- Automatic cut sleeve applicator with shrink wrapping machine

Automatic Round Bar Cutting Machine

We are To cut the dish wash bar in to the pre described length with suitable grammage during extrusion process along with the longitudinal movement of the bar.

Automatic Round Bar Slicing Machine with Conveyor

To slice the Round bar in to 7 Pieces or required by the user ( 500 Gram of equal weight ) with more accuracy and up to the weight variation of +/- 15 Gram. The above machine contains the Hydraulic Power pack and solid jigs for slicing bars and the scrap recycling conveyor.

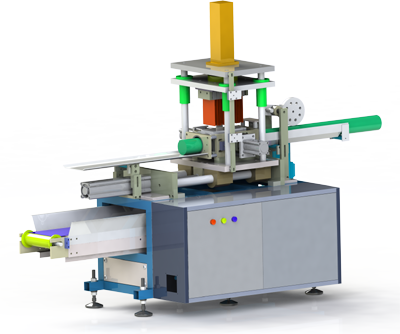

Automatic Dish wash Rotary Stamping Machine with conveyor

To do stamping of company logo and as well as expanding the soap side surface to avoid water seepage in to the bottom of the container. And also it make the bar to stick to the wall of the container to avoid falling and also keep the left out water during washing into the top center portion of the bar.

To do stamping of company logo and as well as expanding the soap side surface to avoid water seepage in to the bottom of the container. And also it make the bar to stick to the wall of the container to avoid falling and also keep the left out water during washing into the top center portion of the bar.

Of course the company logo will be stamped in a new technology which give the aesthetic look to the Bar.

Rotary table to transfer the bars Stamping mc to Chain conveyor

Rotary table transfers the bars after stamping in to the Chain conveyor to move for Scrubber feeding system.

Automatic Top Label & Sleeve Applicator with Shrink wrapping machine with conveyor

It contains three equipments as below.

- Automatic top Label applicator

- Automatic Tamper proof Sleeve applicator and

- Shrink Wrapping machine.

Automatic top Label applicator.

Self adhesive Top lable will be applied on the top of the container automatically on the top of the container one by one. The lables will be loaded in to the machine in roll form with release paper.