Detergent Bar Making Machines

We are Manufacturers and Exporters of detergent bar making machine. We have extensive collection of great quality detergent soap making machine which are custom-made as per client requirement. We are leading manufacturer of detergent soap making machine.

MATCON manufacturers the equipments for detergent powder manufacturing as below.

- Sigma Mixer

- Triple Roll Mill

- Screw Feeders

- Vacuum Flodders

- Automatic Bar Cutting and Stamping Machine

- Auto Feed Conveyor to Packing Machine.

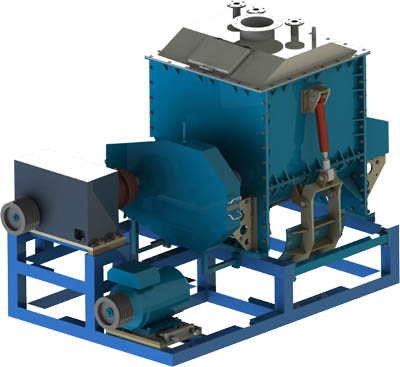

Sigma Mixer

- Sigma mixer is a heavy duty mixer designed for dough mixing which is essential in the soaps , detergents, foods, rubber,chemical industries etc.

- The Z arm or Sigma blade is designed for uniform mixing and criss cross flow of materials.

- The blades rotate in the ratio of 1:1.5 ( 24 : 36 ) rpm

- The mixer is supplied with jacket or without jacket as per the requirement of the customer.

- We supply in different capacities with fully SS, Partly SS and fully MS constructions.

- Discharge is by hydraulic door opening system or through screw rod system.

- Heavy duty gear box and gears are used to withstand high viscous mixing.

- Sigma blades are solidly casted, machined, x ray tested before fitting.

- Minimal uniform gap is maintained between the trough and the blades.

Capacity Range

2000 kgs/ 1500 kgs /1000 kgs / 500 kgs / 250 kgs / 100 kgs / 50 kgs / 25 kgs / 10 kgs Batch Size

Multi Screw Conveyor ( LUMP BREAKER)

Multi Screw conveyor will receive the detergent mass from Zigma Mixer and feed in to the Plodder in a defined quantity. The advantages of above equipment is as below.

- Immediate emptying of Zigma Mixer resulting the batch making time will be reduced.

- Uniform and consistent feeding of detergent mass in to plodder resulting homogeneous mixing of mass and better quality of detergent bar.

- Make the lumps received from Zigma in to uniform size so that the consistent output of plodder will be maintained.

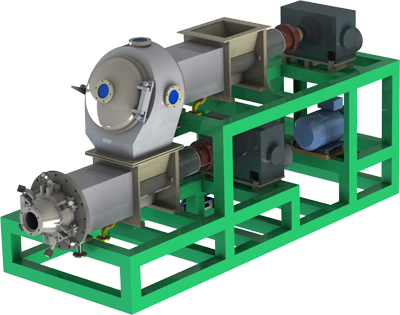

Vacuum Plodder

- Twin Worm Duplex Vacuum Plodder Refines the Soap Mixture to Smooth Bars

- Duplex Plodder Comprise of Pre Plodder and Final Plodders Driven Individually

- The Mixture Is Extruded by Twin Screws in Pre plodder Orifices of Noodle Plate

- Rotary SS Shredders on Worms Cut Equal Lengths Noodles & Pass to Vacc.Chamber

- Vacuum Chamber Connects the Pre Plodder and Final Plodder with Openable Lid

- Final Plodder Compacts the Soaps to A Fine Finished Bar by Its Conical Jacket Mouth

- Twin Cylindrical Barrel Made of SS 304/ MS and Precision Machined Inners

- Barrel Is Constructed with Thick Back Flanges to Match to the Twin Output Gearbox

- The Barrel Is Jacketed and Pressure Tested for Chilled Water Circulation

- Twin Screws Are of 300 mm Dia Each with Left and Right Flutes with Reduction Pitch

- Screws Are Solidly Casted SS 304, X Ray Tested with Flights for Positive Extrusion

- The Worm Shaft Is Supported at the End Through Heavy Duty Thrust Bearing Housing

- One Motor at the Top Stage and another Motor at the Bottom Stage

- Double extrusion mouth with Heating system

Tipple Roller

The Tipple Roller offered by us is included in the soap making plant. The machine is fabricated using high quality raw materials in compliance with latest technology. Our machine is appreciated for durability and quality with efficient performance and low maintenance. Tested on different quality parameters the tipple roller is delivered flawlessly at client’s end.

| TIPPLE ROLLER | |

| H.P. | |

| 8”/20” | 7.5 |

| 10”/20” | 10.0 |

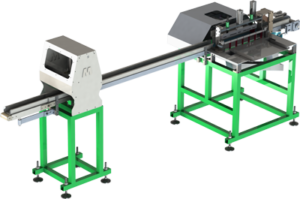

Automatic Soap Cutting and Stamping Machine.

We are engaged in offering a very highly superior quality range of Automatic Soap Cutting and Stamping Machine. These are designed and developed as per the need of our clients. Our products are quality tested at all levels of production. Our range is available at market’s most leading price.

We are engaged in offering a very highly superior quality range of Automatic Soap Cutting and Stamping Machine. These are designed and developed as per the need of our clients. Our products are quality tested at all levels of production. Our range is available at market’s most leading price.

- The automatic soap cutting and stamping machine is used to cut soap bar from the plodder, Cut the soap to billets . and stamp the necessary logo

- The primary cutter cut the bars from the plodder at equal repeat lengths.

- The cutting system works based on the position of the sensor.

- User-friendly system to vary lengths of bars. .

- Bars are conveyed to cutting and stamping machine through a conveyor. .

- The bars are sensed automatically and pushed forward for secondary .

- bar cutting and stamping. .

- The soap bars are dispensed to the off take conveyor to the wrapping machine. .

- The machine is provided with a cutting frame to cut the bars. .

- The trimming waste is taken out by a conveyor and fed to the inclined belt conveyor for cutting waste recycling.

- All the pneumatic components are FESTO / SMC make. .

- Geared motors are from BONFIGLIOLI. .

- The machine is designed with the flexibility for quick change over system between pack sizes.

Features

- High performance

- Long performing life

- Specifically designed

Auto feed Conveyor to Packing Machine

The Rotary Sealing Machines are used for packaging application in different industries. These machines are included in turn key detergent powder, cake & soap plants for packing soaps and detergents. The machine is manufactured using graded materials and components and appreciated for high performance and less maintenance.

The Rotary Sealing Machines are used for packaging application in different industries. These machines are included in turn key detergent powder, cake & soap plants for packing soaps and detergents. The machine is manufactured using graded materials and components and appreciated for high performance and less maintenance.