Conveyor

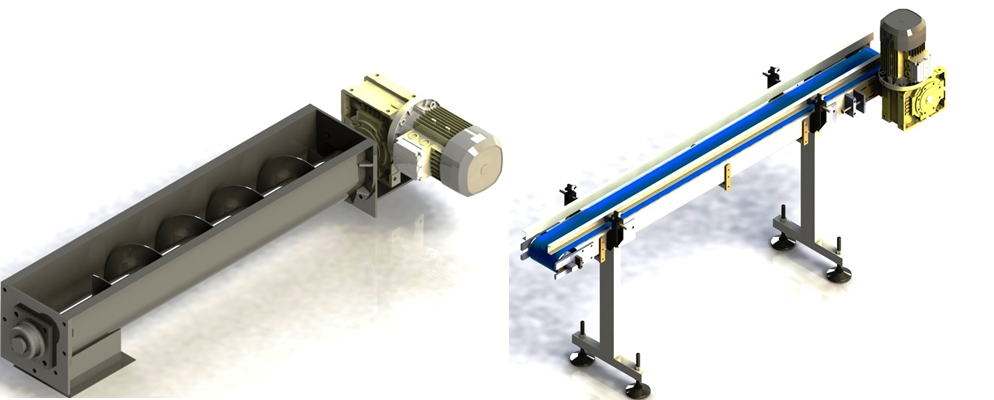

Multi screw Conveyor

Multi Screw Conveyor will receive the detergent mass from Zigma Mixer and feed into the plodder in defined quantity.

The advantages of Multi Screw Conveyor are,

- Immediate emptying of Zigma Mixer results in reducing the batch making time.

- Uniform and consistent feeding of detergent mass into the plodder resulting homogeneous mixing of massvand better quality of detergent bar.

Belt & Screw Conveyor

A screw conveyor is a mechanism that uses a rotating helical screw blade, called a “ flight”, usually within a tube, to move the granular materials. It is often used horizontally or at a slight incline as an efficient way to move semi – solid materials.

Screw conveyor usually consist of a trough or tube containing ether a spiral blade coiled around a shaft, driven at one end and held at the other driven at one end and free at other. The rate of volume transfer is proportional to the rotation rate of the shaft.

Belt conveyor system consist of two or more rollers with an endless loop of carrying medium the conveyor belt rotates among them. It is generally used in soap & detergent industries to transport large volume of products within a certain time period.

Swept Conveyor

Swept conveyor is used to transfer the detergent powder from the respective silo / elevators to the feeding hoppers of packing machines. It transfers the detergent powder by just pushing the powder with the blades and hence the free flow of the detergent powder gets maintained. The compression of detergent powder get avoided.

It will be having the bottom and the end discharge ports. Any no of packing machines can be mounted below the swept conveyor according the length of the conveyor.

The size and the capacity varies according to the customer requirements.

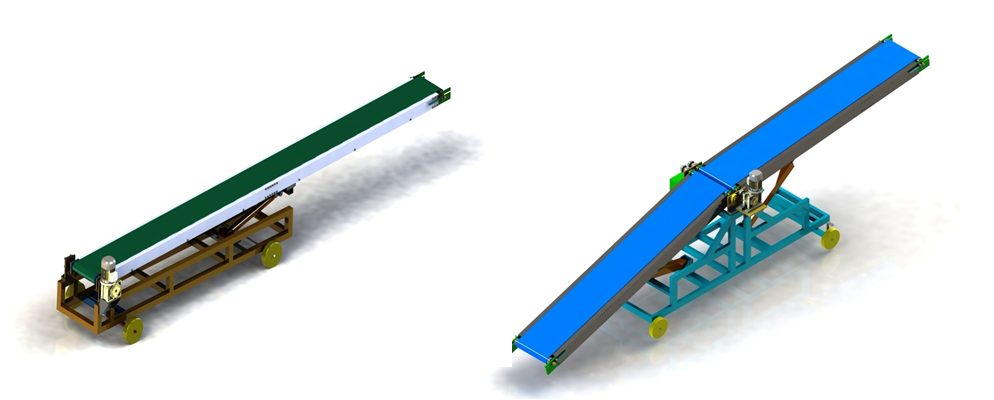

Loading and Unloading Conveyor

Loading and unloading conveyors are custom designed and fabricated as per the needs of the application and can be customized for dimensions, conveying capacity & loading / unloading capacity required according to the material to be conveyed.

Our Loading Conveyors provide highly efficient and time saving solutions for loading bulk materials.

Salient Features:

- Height adjustable boom for better reach inside the Plant / Container.

- Study & Mobile conveyor chassis.

- Can be customized for any type of loading capacity or requirement.

- Robust construction and field tested design for long life trouble free operation.

Roller Conveyor

Loading and unloading conveyors are custom designed and fabricated as per the needs of the application and can be customized for dimensions, conveying capacity & loading / unloading capacity required according to the material to be conveyed.

Our Loading Conveyors provide highly efficient and time saving solutions for loading bulk materials.

Salient Features:

- Height adjustable boom for better reach inside the Plant / Container.

- Study & Mobile conveyor chassis.

- Can be customized for any type of loading capacity or requirement.

- Robust construction and field tested design for long life trouble free operation.